RPC Business Division

Business Unit Introduction

The RPC (Rice Processing Complex) business unit establishes the entire process essential for producing high-quality grains, based on drying, storage, and processing technologies for post-harvest grain processing.

This business unit internally produces most of the unit machinery required for processing, and conducts business through Turn-Key contracts based on system engineering, from design to construction and commissioning for the entire process.

DSC (Drying and Storage Center)

A drying and storage facility refers to equipment that rapidly brings in locally produced goods, dries and stores them after proper sorting. It shares the same structure as RPC's intake, sorting, drying, and storage units, excluding the grain processing unit.

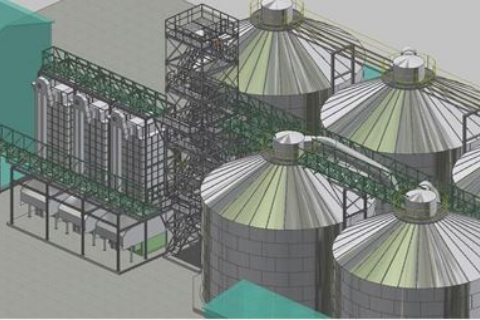

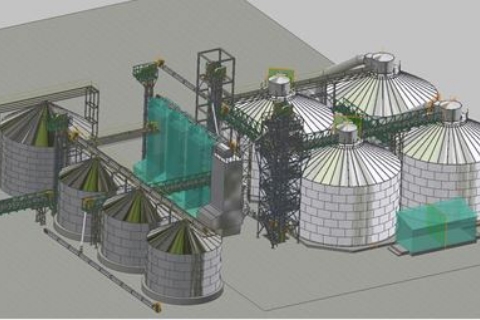

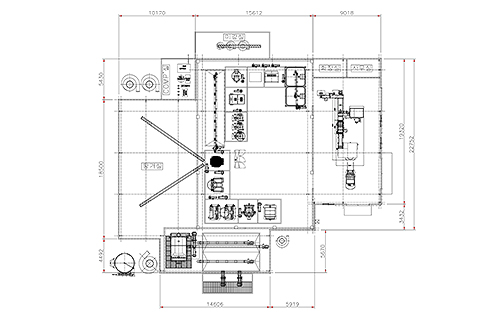

3D Modeling Design & Structural Simulation

The structures constituting the plant are precisely designed down to the smallest detail through 3D modeling, minimizing errors during actual construction, and optimal structural calculations are derived through computer simulations and applied to real construction.

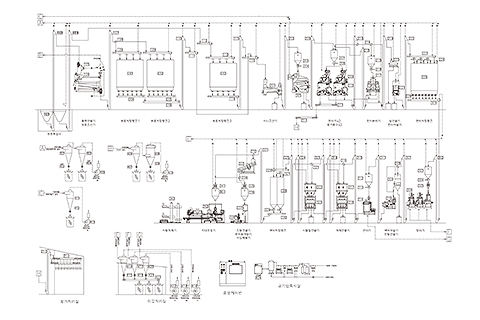

RPC Process

Grains transported from the field are accurately measured for moisture and mass through an automated intake system, resulting in precise intake measurements.

-

Intake Part

-

Wind Force Separator

-

Pre-Cleaner

-

Hopper Scale

Link to Rice Variety Analyzer

It scientifically determines if there is any adulteration in mixed rice and whether labeling and contents match based on factual evidence. It also rapidly determines matching varieties based on information from various regions nationwide.

The received grains are dried to the appropriate moisture level for storage through grain dryers, and the dried grains are transported to grain storage silos.

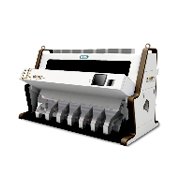

Subsequently, the grains are transferred to the processing unit, where, in the case of rice, they undergo polishing of white and brown rice, color sorting to determine the final quality of the grains, and a metal detection process.

-

Flow Meter

-

Mini Pre-Cleaner

-

Vacuum Type Destoner

-

Paddy Husker

-

Vacuum Type Aspirator

-

Sealed Type Aspirator

-

Paddy Separator

-

Thickness Grader

-

Aspirator Stoner

-

Vibration Separator

-

Rice Whitener

-

Rice Polisher

-

Rice Blending Machine

-

Color (Foreign Material) Sorter

-

Grain Cooler

-

Flow Meter

-

Metal Detector

-

Grain Storage Tank

Management System

-

Example of a process

-

LAY OUT Example

Link to Rice Quality Analyzer

By implementing an integrated quality management system, it enhances yield and grain quality, providing tailored quality management systems.

Grains that are determined to be of high quality through these processes proceed to the packaging unit, where they are packaged into various sizes according to the producer's preferences.

-

Automatic Weighing and Packaging Machine

-

Semi-Automatic Weighing Scale

-

Semi-Automatic Sewing Machine

-

Plastic Bag Sealing Machine

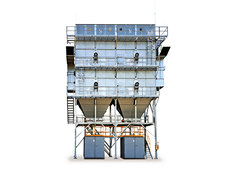

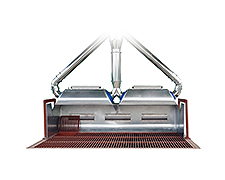

Furthermore, installations include a vortex-type hood at the intake, centrifugal dust collectors for major facilities, and integrated dust collection equipment to maximize dust prevention and handle byproducts generated during the grain processing process.

-

Integrated Bag Filter

-

Centrifugal Dust Collector

-

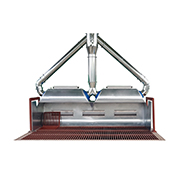

Vortex-Type Hood

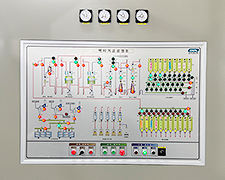

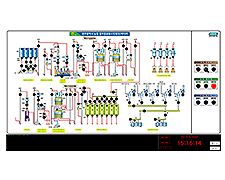

The entire RPC process is automatically controlled through a computerized operation and management program (intake management, grain temperature management, inventory management, yield management, production management, record-keeping) in the central control room.

-

Interior of Central Control Room

-

Control Panel

-

Automated Control Program

Smart RPC Solution

Computerization of all tasks in the comprehensive grain processing facility and providing consumers with the history and quality information of rice, offering solutions to improve yield, grain quality, and productivity while conserving energy.

Link to Smart RPC Solution Link to RPC Equipment Shortcut