Environmental Business Division

Air Pollution Prevention Project

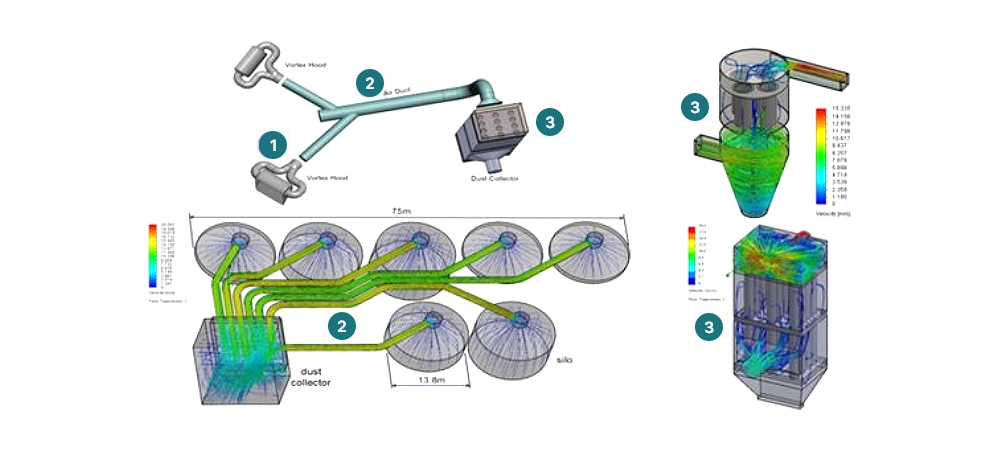

Ideal System has developed technology in collaboration with national research institutions to effectively capture particulate matter (PM) in the air. Through various computational fluid dynamics simulations, we analyze the flow of air currents, basing our results on accurate data to maximize the efficiency of dust collection equipment. Utilizing this technology, the vortex-type hood and integrated dust collection system are representative environmental solutions provided by Ideal System

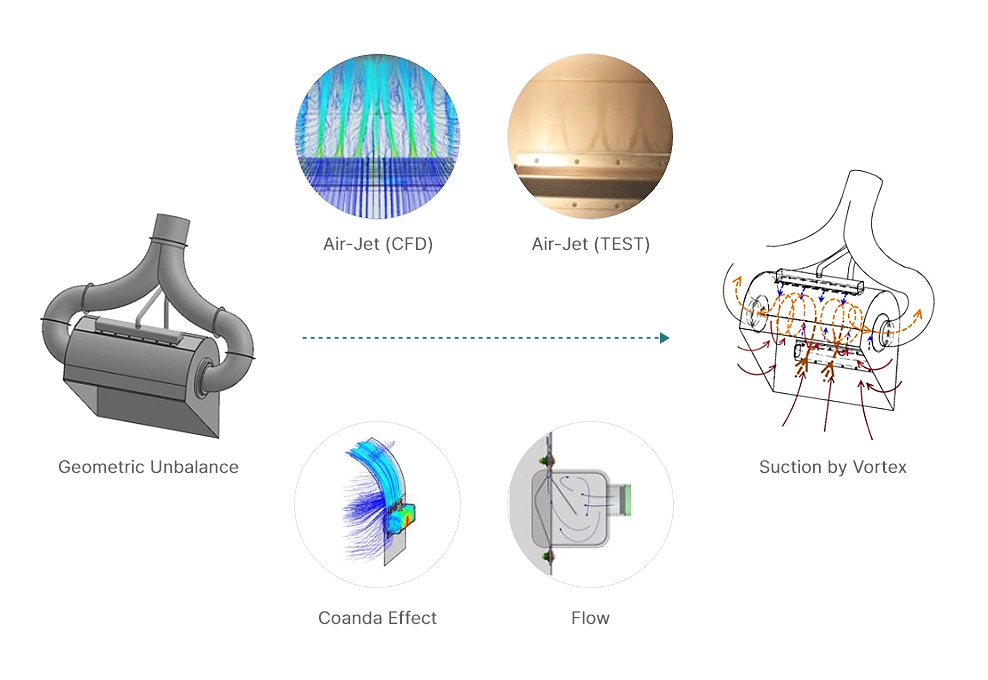

Leveraging state-of-the-art design technology, the vortex-type hood utilizes the unique Coanda Effect of air currents to achieve over 40% improvement in dust collection efficiency compared to conventional commercial hoods, all while using the same amount of power.

Vortex-type Hood Construction and Performance Testing

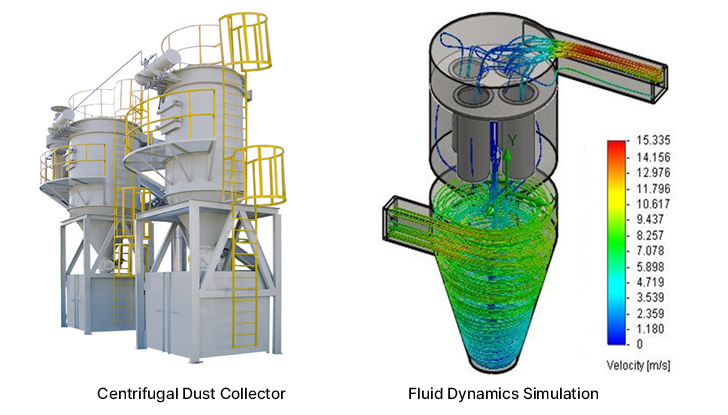

The centrifugal dust collector is an advanced system that combines cyclone and bag filter methods to efficiently collect both large particles and fine dust simultaneously. It is designed with an optimized structure for capturing dust based on fluid dynamics simulations.

Energy-efficient integrated bag filters provide customized dust collection solutions based on fluid dynamics simulations for each facility. Through 3D simulations, optimal duct designs can be achieved, allowing effective dust collection with less power. It also prevents the phenomenon of dust accumulation and blockage in ducts due to incorrect power calculations.

Dust Collection System: Purification of contaminated air containing dust and particles in large workspacesComponents

- 1 Hood

- 2 Air Transport Duct

- 3 Dust Collector

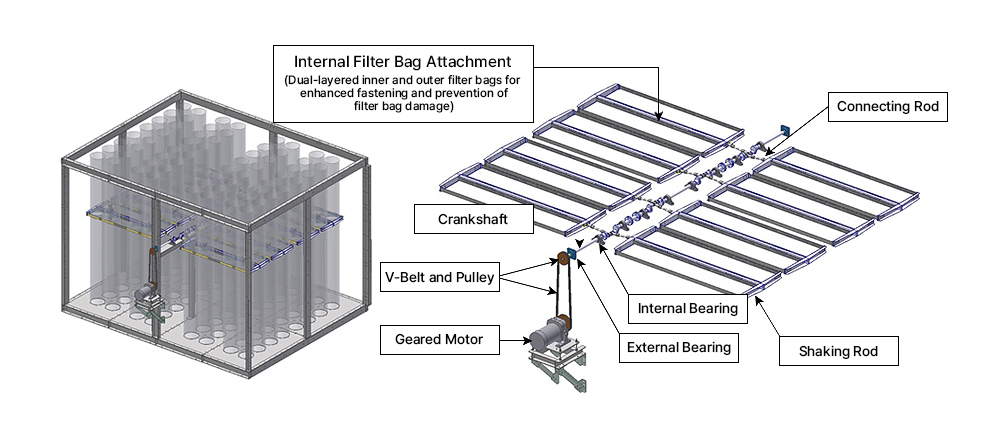

In addition, we have moved away from the traditional Air-Purse method, which relies on conventional air compressors, and adopted a vibration-based dust removal method (Shaking Device Type). This has maximized dust collection efficiency and significantly reduced power consumption.

Detailed Structure of Integrated Bag Filter Dust Removal Device