Management Systems

Smart Solutions

- Establishment of an Integrated Information Platform based on Big Data

- System for Purchasing and Sales Settlements, Yield, and Inventory Management

- In-house Development of Automated Data Collection System

- Production Management System

- Establishment of Crop Cultivation History, Production History, and Quality Information Platform

- Providing Cultivation, Production History, and Quality Information (Consumer Protection)

-

Enterprise Resource Planning (ERP) & Nonghyup Economic Integration System

-

Smart RPC System

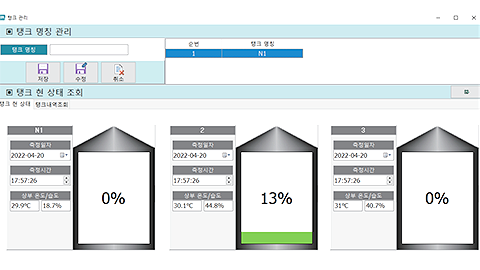

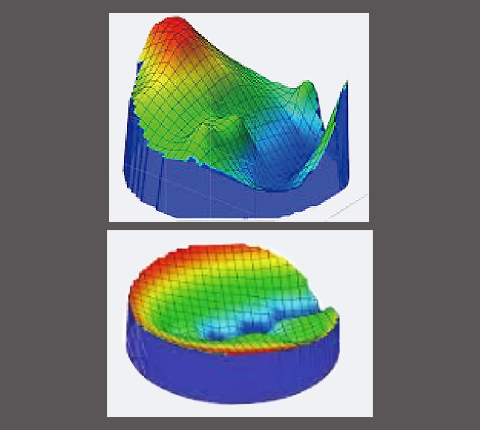

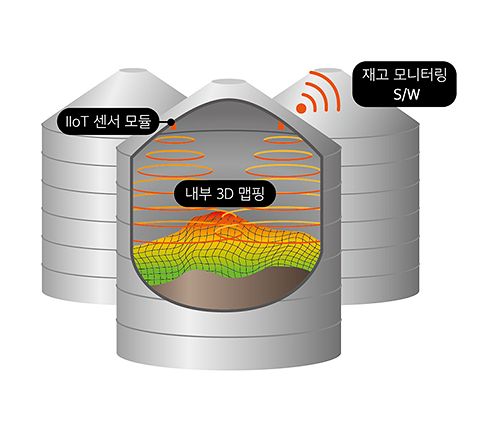

- Inventory Management System

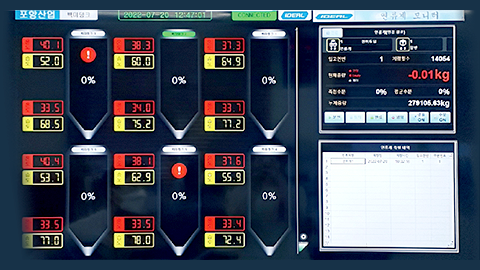

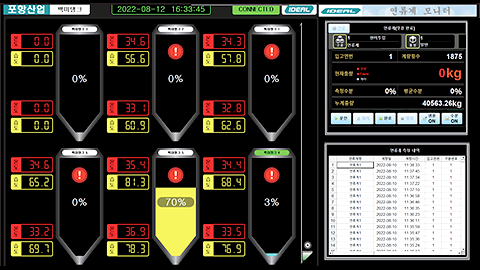

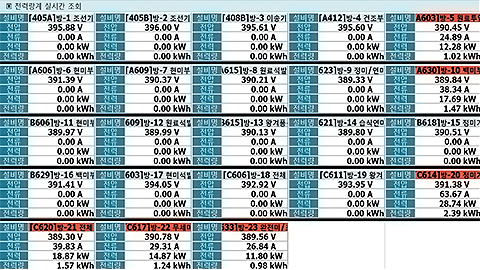

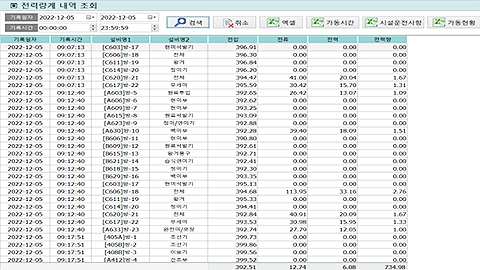

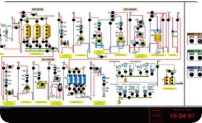

- Smart Monitoring System

-

-

Cold Storage Warehouse

-

Silos

-

DSC

(Drying Storage Complex) -

RPC

(Rice Processing Complex)Inbound, Input, Drying & Storage Department, Processing Department, Packaging Department

-

- Grain Processing Plant

- Agricultural Products Distribution Assurance Center (APC)

- Miscellaneous Grain Sorting and Packaging System (SPC)

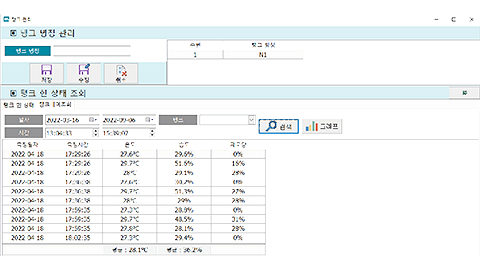

- Grain Storage Tank Management System

- Automated Warehouse Material Movement Management

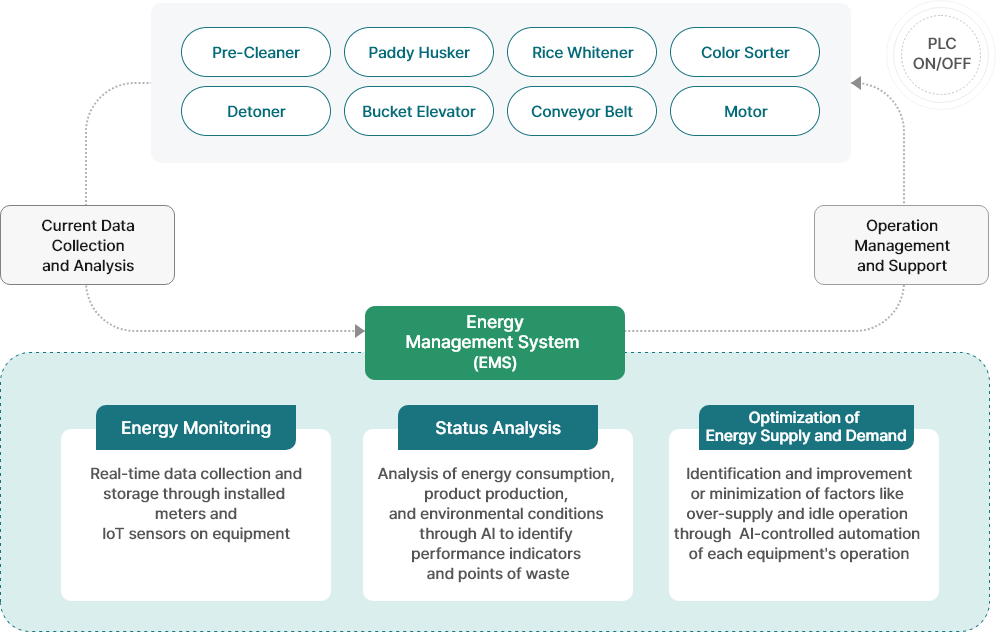

- Smart Energy Monitoring System

Solution for Grain Processing and Distribution Industry

- Leading the Smart Transformation of the Grain Processing and Distribution Industry through the Establishment of a Smart Factory Platform via Technology Transfer from the Korea Food Research Institute.

- The Nonghyup Rice Processing Complex (RPC) is managed smartly through an AI and IoT-based Smart RPC Production and Distribution Management System.

- Building an Integrated Information Platform based on Big Data collected throughout the entire process of Grain Processing and Distribution.

-

-

Rice Cultivation

-

Cultivation History

Farmland Management Data

GIS-based Farmland-specific

Cultivation History Management System

-

Drying and Storage Facility

-

Purchased Paddy Rice

Drying and Storage Data

Grain Purchase Settlement &

Storage Inbound/Outbound Inventory Management System

-

Grain Processing Facility

-

Sorting, Processing, Packaging

Production and Quality Data

Smart RPC Production Management System

-

Market Distribution

-

Product Production History Inquiry(Variety, Production Date, Origin, Crop Batch, Quality Information, etc.)

History and

Quality Information System

-

-

- Information Analysis

-

- Estimated Rice Production Volume

- Determination of Appropriate Purchase Price

- Analysis of Crop Yield by Period

- Improvement of Cereal Policies

- Establishment of Optimal Quantity Purchase Plans

- Benefits

-

- Customized Rice Production for Customers

- Safe Food Supply

- Enhanced Quality Control

- Expansion of High-Quality Rice Exports

-

CLOUD RPC Integrated Information Platform for the Cereal Processing and Distribution Industry

Production Equipment Solutions

- We have independently developed an automated data collection system for production and quality-related data from various production lines.

- We possess hardware and software construction skills required for IoT-based AI Smart Factory establishment, as well as AI algorithm design skills.