SPC Business Division

Business Unit Introduction

SPC (Soybean Processing Complex) business unit is equipped to establish the entire process necessary for post-harvest processing of various legumes and cereals, including soybeans and seeds, based on sorting, processing, and packaging technologies, aiming to produce high-quality cereal products.

This business unit internally produces most of the unit machinery required for processing, and conducts business through Turn-Key contracts based on system engineering, from design to construction and commissioning for the entire process.

-

Pulse Sorting Line

-

Cereal Sorting Line

3D Modeling Design & Modularization

Structures comprising the plant are precisely designed down to small components through 3D modeling, minimizing errors during actual construction. Optimal structural calculations are derived through computer simulation and applied to real construction.

Furthermore, pioneering modularization in the industry enables perfect production and construction quality, shortened lead times, reduced air consumption, and cost savings, allowing for smart operational management.

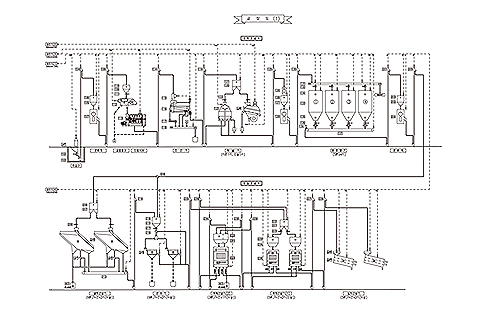

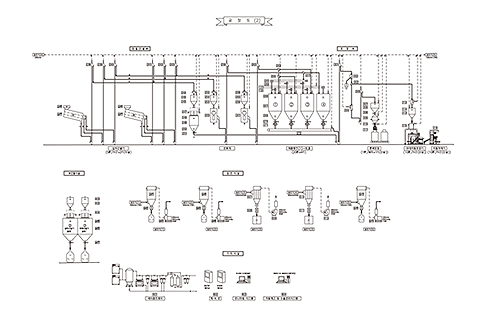

SPC Process

The post-harvest processing system for grains and miscellaneous crops (beans, peas, barley, sorghum, millet, sesame, corn) is a system that consistently handles processes such as procurement, drying storage, processing, sorting, and packaging. We focus on improving yield and quality.

-

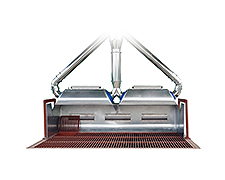

- 1 Vortex-type Hood (Raw Material Input)

-

Generates air currents within the hood to maximize dust collection efficiency

- 1

-

- 2 Wind Force Separator

-

Sorts out larger foreign objects using air currents

- 2

-

- 3 Pre-Cleaner (Bean Cleaner)

-

Sorts out foreign objects from input materials

- 3

-

- 4 Raw Material Destoner

-

Uses vacuum suction to separate stones and foreign objects

- 4

-

- 5 Flow Meter

-

Measures the weight of input materials

- 5

-

- 6 Raw Material Tank

-

Stores sorted raw materials

- 6

-

- 7 Size Sorter & Particle Sorter

-

Separates defective grains into large, medium, and small categories based on size

- 7

-

- 8 Gravity Separator

-

Sorts out defective grains and foreign objects based on density differences

- 8

-

- 9 Product Tank

-

Stores sorted raw materials categorized as large, medium, and small

- 9

-

- 10 Belt Sorter (Broken Bean Sorter)

-

Sorts broken beans using an inclined belt system

- 10

-

- 11 Polishing Machine

-

Removes impurities and adds gloss to the surface of grains

- 11

-

- 12 Color Sorter

-

Uses color cameras to sort grains based on color and remove impurities

- 12

-

- 13 Product Tank

-

Stores sorted raw materials

- 13

-

Example of a process

-

Example of a process

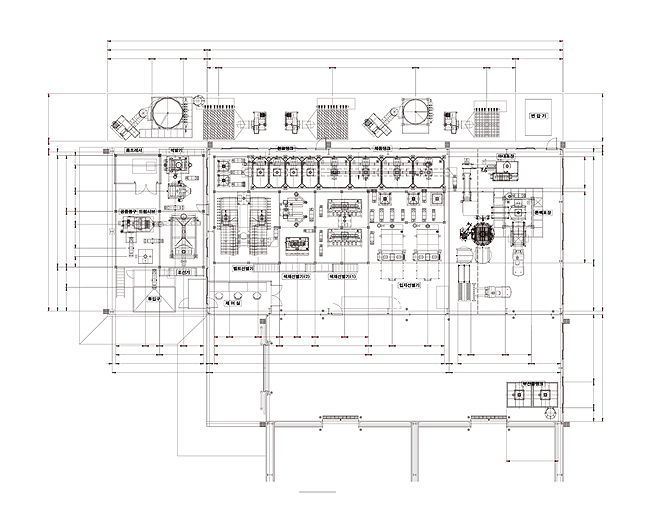

LAY OUT Example

Grains and pulses determined to be of high quality through these processes proceed to the packaging unit, where they are packaged into various sizes according to the producer's preferences.

-

Semi-Automatic Weighing and Packaging Machine

-

Grain Measuring Machine

-

Semi-Automatic Mixing Machine

-

Plastic Bag Sealing Machine

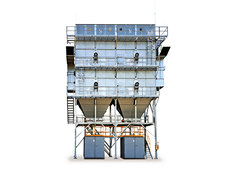

Furthermore, installations include a vortex-type hood at the intake, centrifugal dust collectors for major facilities, and integrated bag filters to maximize dust prevention and handle byproducts generated during the grain processing process.

-

Integrated Bag Filter

-

Centrifugal Dust Collector

-

Vortex-Type Hood

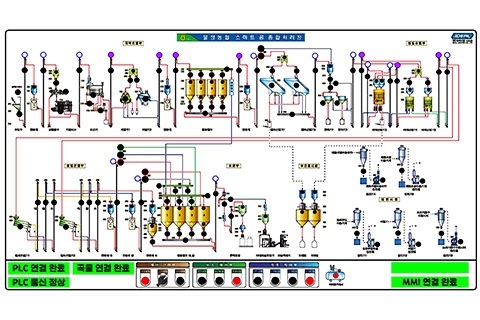

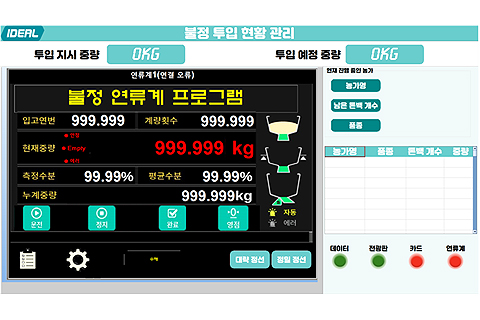

The entire SPC process is automatically controlled through a Smart SPC Operation and Management Solution (intake management, inventory management, production management, Traceability management, yield management, quality management) in the central control room.