Smart Solution Business Division

Introduction to the Business Unit

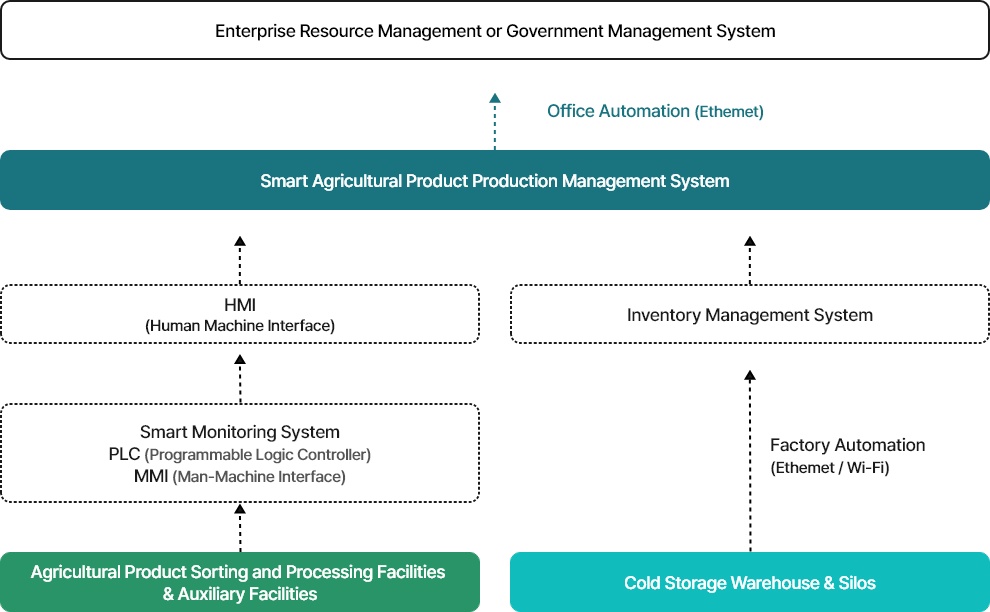

The Smart Solutions Business Unit leverages the technological convergence and innovation of manufacturing and ICT through the Fourth Industrial Revolution. By integrating information and communication technology with the traditional methods of manufacturing, we establish smart factories and analyze integrated production information to provide tailored smart solutions to our clients' manufacturing sites.

We achieve this by digitizing operations, automating the collection of production data, establishing comprehensive quality management systems, and implementing monitoring systems. Through the development of a smart agricultural product production management system, which encompasses digitalization, automated data collection, and the integration of a comprehensive quality management system, we strengthen food security and proactively address the volatility of the global supply chain.

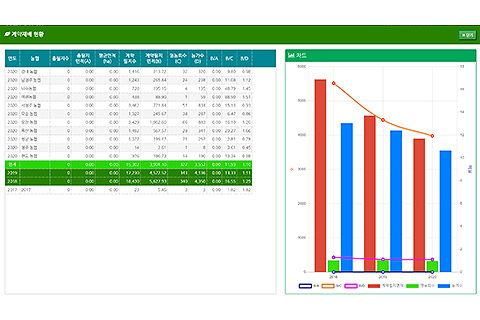

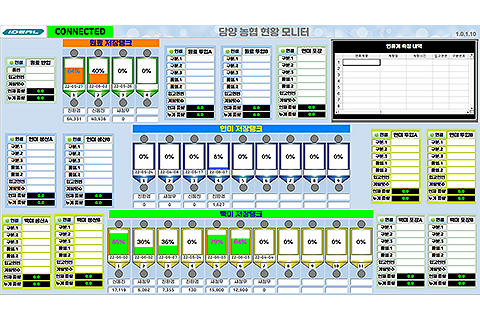

Contract Farming & Incoming (Purchasing) Management System

Customized real-time monitoring of cultivation management, inbound and outbound processes, inventory, and grain temperature control for each plot.

Inbound History Management, managing input weight by customer and variety, with display on the dashboard specifying the order of input by customer. Linked to moisture and weight measuring devices for remote control, and capable of managing settlements and printing through procurement records.

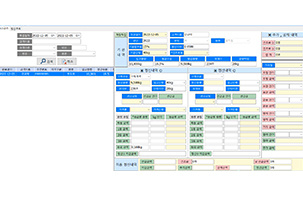

Inbound History / Warehouse Movement Management System

During inbound, customer information, variety, and weight are entered through RFID tag attachment, enabling warehouse-specific inbound, outbound, and inventory details to be checked, allowing current status to be monitored.

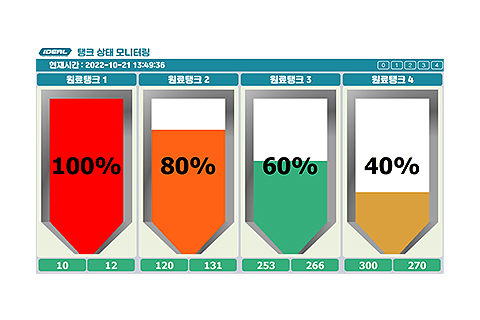

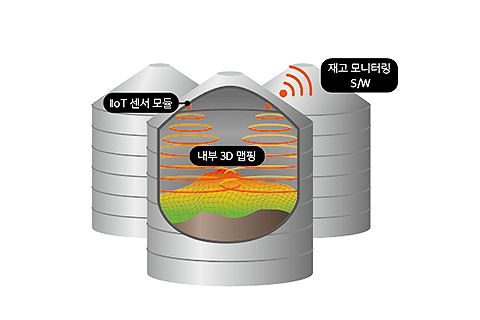

Real-time Product Tank Monitoring System

IoT sensor-based status monitoring provides information on remaining material and product tank levels, and for storage silos, a vision center is applied to visualize the interior in 3D and calculate volume and weight, enabling accurate inventory management.

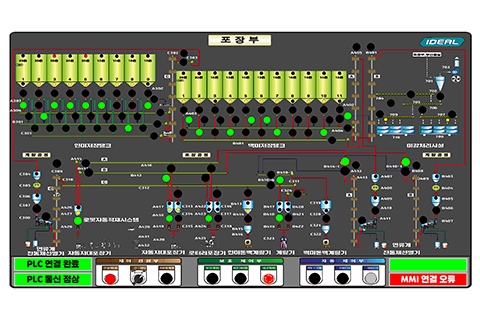

Sorting Yield Management System

Through linkage with the MMI, material, product, packaging, and byproduct flows of the entire line can be displayed at a glance, allowing for sorting yield confirmation and control.

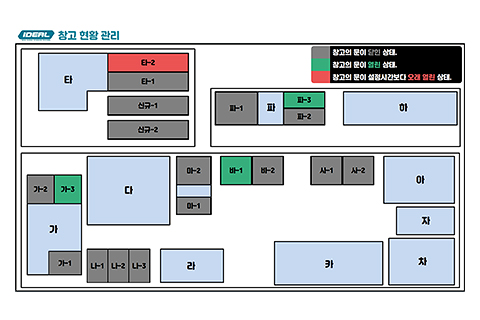

Low-Temperature Warehouse Opening and Closing Monitoring System

Sensors attached to doors monitor opening and closing status, time, and timing, enabling power management and sounding an alarm for extended door opening.

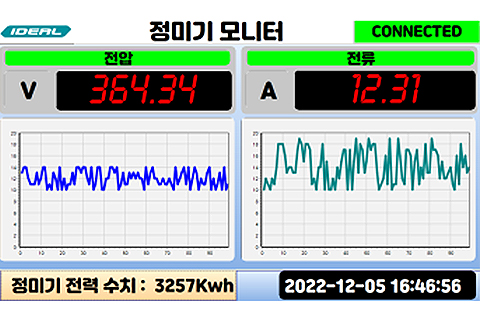

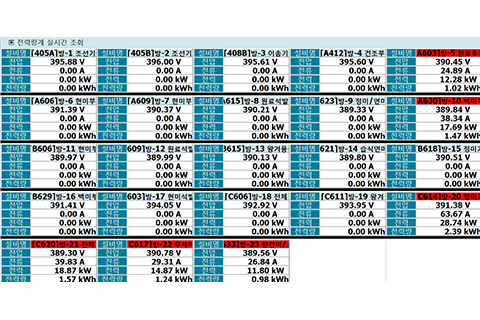

Smart Energy Management System

By analyzing energy consumption for each equipment and process, automatic power supply control extends the lifespan of equipment and consumables and efficiently manages energy. In addition, data from power meters installed at each site is collected, enabling management by day and time.